Reduction of CO2 Emissions

Our Approach to Reducing CO2 Emissions

To reduce CO2 emissions, a cause of climate change, the Kewpie Group is actively working for energy conservation and an energy shift in entire value chain: procurement, production, logistics, sales, and offices.

As part of the Kewpie Group's efforts to deal with climate change a key sustainability issue, we are working to further implement our response to climate change, having set our own domestic CO2 emission reduction targets for the Group in Japan.

Reduction of CO2 Emissions

The Kewpie Group is calculating CO2 emissions throughout its supply chain and promoting initiatives to further reduce CO2 emissions.

Besides existing initiatives such as improving the efficiency of manufacturing processes and introducing energy-saving equipment, the entire Group is advancing on reforms of manufacturing methods and processes for a decarbonized society, and the introduction of renewable energy.

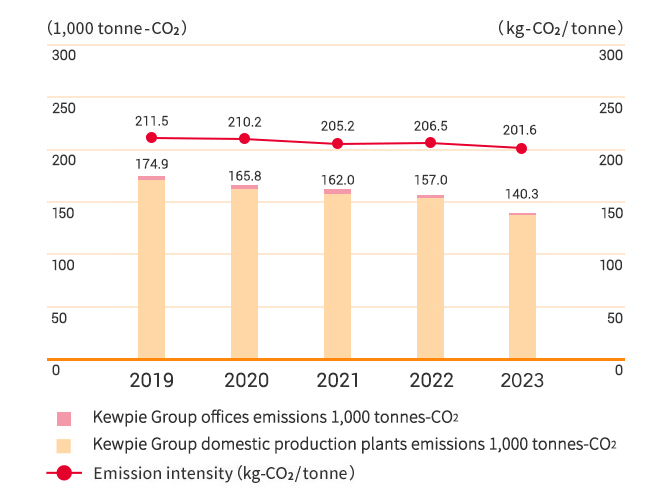

CO2 Emissions

Making Use of Renewable Energy

The Kewpie Group is progressively introducing renewable energy in Japan and in other countries.

In FY2024, we installed solar panels at one new business site in Japan, bringing the number of business sites incorporating renewable energy to 18 domestic and six overseas sites, as we continue making progress in our efforts to reduce CO2 emissions.

The installation of 384 solar panels at the Salad Club Mihara Plant covers approximately 10% of total electricity consumption using solar power, contributing to a reduction of approximately 113.5 tons of CO2 emissions annually.

Installation status

| Start of power generation | Site |

|---|---|

| Jan 2025 | Salad Club Kpack Goka Plant |

| Aug 2024 | Salad Club Mihara Plant |

| Aug 2023 | Co-op Foods Co., Tohoku Plant |

| Jun 2023 | Kewpie Egg Corporation, Owari Plant |

| May 2023 | Kewpie Malaysia Sdn. BHd. |

| May 2023 | Guangzhou Kewpie Corporation |

| Mar 2023 | Salad Club, Enshu Plant (Phase 2) |

| Mar 2023 | Kewpie Egg Corporation, Mita Plant |

| Jan 2023 | Nantong Kewpie Corporation |

| Aug 2022 | Kitakami Delica Co. (onsite PPA model) |

| Mar 2022 | Beijing Kewpie Co. |

| Jan 2022 | Kewpie Kobe Plant (on-site PPA model) |

| Dec 2021 | Kewpie Vietnam Co. |

| Feb 2021 | Kewpie Egg Corporation, Hanno Plant |

| Feb 2021 | Shunsai Deli Co., Ome Plant |

| Apr 2020 | Shunsai Deli Co., Akishima Plant |

| Feb 2020 | Kewpie (Thailand) Co. (Phase 2) |

| Apr 2018 | Kewpie (Thailand) Co. (Phase 1) |

| Mar 2017 | Green Factory Center Shirakawa* (Phase 2) |

| Dec 2016 | Kewpie Goka Plant |

| Mar 2016 | Salad Club, Enshu Plant (Phase 1) |

| Sep 2015 | Kewpie Egg Corporation, Fuji Yoshida Plant |

| Jan 2015 | Green Factory Center Shirakawa* (Phase 1) |

| Apr 2014 | Kewpie Jyozo Co., Shiga Plant |

| Oct 2013 | Sengawa Kewport |

| Apr 2013 | Kpack Co., Head Office Plant |

| Mar 2012 | Kewpie Fine Chemicals Main Branch, Goka Plant |

*Fujiyoshida Kewpie Co. transferred the business in 2021, and Green Factory Center Shirakawa withdrew from the business in 2023. Kewpie Corporation continues to own and manage the photovoltaic panels installed on the site.

Solar panels installed at the Salad Club Mihara Plant

TCFD Initiatives

The operations of the Kewpie Group are highly dependent on the blessings of nature. Accordingly, these operations could incur impact from climate change in a variety of ways, including through lower harvest yields and reduced quality of ingredients. Moving forward, we will address and respond to future climate-change related events as management risks, while at the same time identifying new opportunities and incorporating them into our corporate strategies.

The Kewpie Group endorses the Task Force on Climate-related Financial Disclosure (TCFD)*1 and has joined the TCFD Consortium,*2 which serves as a forum for collaborations among companies and financial institutions that support TCFD. Internally, the Kewpie Group created the TCFD Project and has engaged in its own initiatives since 2021.

*1Established by the Financial Stability Board (FSB) in 2015 at the behest of the G20. The TCFD recommends that companies assess the financial impacts of climate change risks and opportunities on management and disclose information pertaining to governance, strategies, risk management, metrics and targets.

TCFD website

*2Established in 2019 as a forum for discussing efforts leading to effective corporate information disclosure and the disclosure of information facilitating appropriate investment decisions by financial institutions and other organizations. Companies and financial institutions that support the TCFD recommendations are promoting the initiative.

TCFD Consortium website

TCFD Analysis Plan

| Fiscal Year | Scope | Reports |

|---|---|---|

| FY2024 | Mayonnaise, dressings, eggs, cut vegetables, prepared dishes (potato salad) | |

| FY2023 | Mayonnaise, dressings, eggs, cut vegetables | |

| FY2022 | Mayonnaise, dressings, eggs (liquid eggs, processed products) | |

| FY2021 | Mayonnaise, sesame dressing |

Production Initiatives

Reducing CO2 Emissions by the Production Division

The Kewpie Group is committed to saving energy by improving the efficiency of production processes and by installing new equipment. We are converting from using Heavy Fuel Oil A to city gas and natural gas, and we are promoting the use of co-generation and solar power. We are also working to reduce CO2 emissions by sharing and developing the outstanding initiatives taken by group plants.

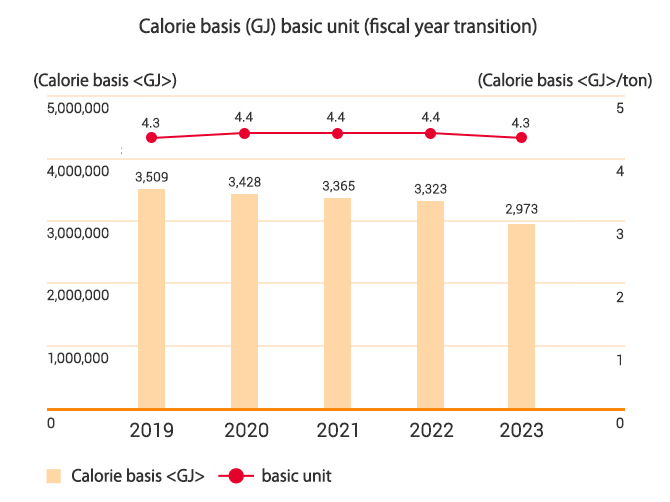

Promoting Energy Conservation in the Production Division

The Kewpie Group is promoting the "visualization of energy use" by installing energy measurement devices in all processes at production sites, improving facility operation and maintenance, and introducing energy-saving equipment to promote energy conservation.

Energy Conservation Reduction Targets for the Production Division

- Reduce energy consumption by 1% or more from the previous year.

Targeted plants: Kewpie Group production plants

The decrease in consumption and the basic energy unit is mainly due to efficient production through factory reorganization regarding condiment products, efficient production through business reorganization in the egg business, and planned energy-saving facility upgrades for each business.

Utilizing Natural Refrigerants

The Kewpie Group is installing energy-saving equipment and working to optimize the operation of our facilities. By incorporating natural refrigerants when upgrading our freezer units, we have reduced CO2 emissions and eliminated fluorocarbon use.

Ammonia freezer units

Installation status

| Year installed | Site |

|---|---|

| 2024 | Kewpie Egg Corporation, Tsukuba Plant |

| 2023 | Kewpie Egg Corporation, Owari Plant Kewpie Egg Corporation, Tsukuba Plant |

| 2021 | Kewpie Egg Corporation, Owari Plant |

| 2020 | Kewpie Egg Corporation, Itami Plant |

| 2018 | Kewpie Nakagawara Plant |

| 2015 | Kewpie Egg Corporation, Tsukuba Plant |

Logistics Initiatives

The Kewpie Group is collaborating with business partners and Group companies to reduce the environmental burden of all transport and delivery operations, from the transportation of raw materials to the delivery of products.

We are working to improve efficiency by shortening transportation and delivery distances and by improving load efficiency. We also implement eco-friendly driving, which consumes less fuel and offers greater safety. Furthermore, we are promoting a modal shift from long-distance truck transportation to rail and ship to reduce CO2 emissions.

CO2 Emissions from Transportation and Delivery

| FY2023 | FY2024 | Year-on-year comparison | ||

|---|---|---|---|---|

| Kewpie products | Transport volume (1,000 tonne-km) | 124,914 | 121,802 | -2.5% |

| CO2emissions (tonnes) | 20.2 | 19.9 | -1.5% |

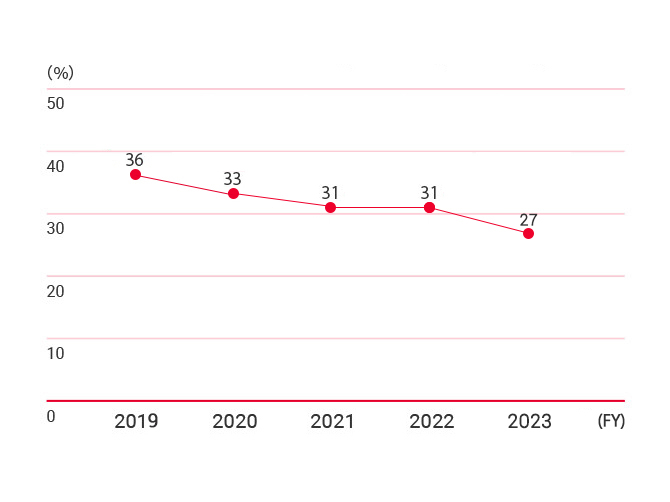

Promoting a Modal Shift

We acquired ten exclusive-use 31-foot containers (of which four are freezer containers) and are coordinating with transportation professionals to promote modal shifts.*1

In July 2019, Kewpie was certified with the Eco Rail Mark as a company that uses cargo trains for more than a certain percentage of product transportations.

*1Modal shift: Shifting long-haul trucking of 500 km or more to container transportation via railroads and ships.

We acquired six 31-foot containers for rail and ship transport and are promoting modal shifts in coordination with freight carriers.

Change in the modal shift ratio

*Modal shift ratio: Ratio of tonnes shipped by railroads and ships to total tonnes shipped 500 km or more.

Joint Transportation Initiatives with Businesses in Other Industries

Since 2018, Kewpie has been conducting joint transportation with Lion Corporation in the toiletries industry and Japan Pallet Rental Corporation in the pallet rental industry; by loading the cargo of the three companies, we have been able to reduce the number of trucks traveling empty to less than 1%.

In addition, a modal shift from trucks to ships for some sections has further increased the CO2 reduction effect.

Office Initiatives

Since February 2022, we have been procuring electricity with environmental value (FIT Non-Fossil Certificate with Tracking)* generated by photovoltaic panels at three sites in Japan. By allocating this electricity, procured from the Japan Electric Power Exchange via TEPCO Energy Partner, Incorporated, we have transitioned to having the electricity used at the Kewpie Shibuya Head Office and Sengawa Kewport being sourced from 100% renewable energy.

*This is a certificate representing the "value being derived from a non-fossil power source" of electricity generated by a non-fossil power source. The certificates are procured by retail electricity providers in the non-fossil value trading market and used in electricity sold to customers, thereby allowing them to reduce greenhouse gas emissions.

Initiatives at the Shibuya office

The Shibuya office (Shibuya Toyu Building) of the Kewpie Group has a double-skin glass facade that achieves a high degree of thermal insulation from natural ventilation between the glass layers. The office has installed highly efficient air conditioners, LED lighting, and other energy saving equipment.

The double-skin glass facade of the Shibuya office.

hrough such environmental designs, the Shibuya office building has been given an overall rating of A by the Comprehensive Assessment System for Built Environment Efficiency (CASBEE).

In addition, the building has been designated a project for receiving interest subsidies to promote green financing.*

*Project for receiving interest subsidies to promote green financing: These are projects selected through a public offer by the Ministry of the Environment to receive a subsidy for part of the interest paid on the financing of capital expenditures addressing global warming.

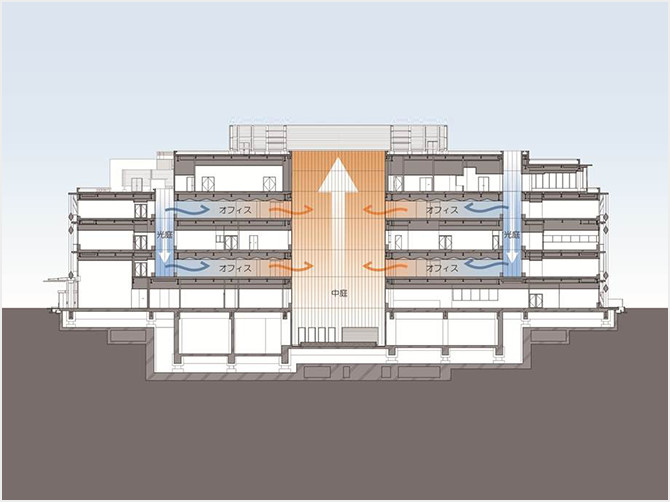

Initiatives at Sengawa Kewport

Natural ventilation system

Energy saving features of Sengawa Kewport include air wells providing natural ventilation, a co-generation system, solar power generation, and LED lighting. To maximize the performance of energy saving design, we are deepening our collaboration with equipment makers and are surveying many employees at Sengawa Kewport to operate energy saving equipment more precisely.

Furthermore, in collaboration with Tokyo Gas Engineering Solutions Corporation, we established an optimized operational pattern based on weather forecast data and the operating status of air conditioners (chillers, heat pumps, gas boilers, and cogeneration power generation) using AI on a cloud server. We are taking further steps to automate driving.